Pressure switches are part of the safety chain, and vital to the safe operation of a combustion system. They are used to verify gas and air pressure, and they can be used to determine whether the gas valves are leaking.

How does a pressure switch work?

Pressure switches are simple devices that use a spring and a rubber diaphragm to actuate a switch. They can be used to monitor rising, falling, differential, and negative pressures, and many models of pressure switch can monitor more than one type of pressure change depending on the wiring.

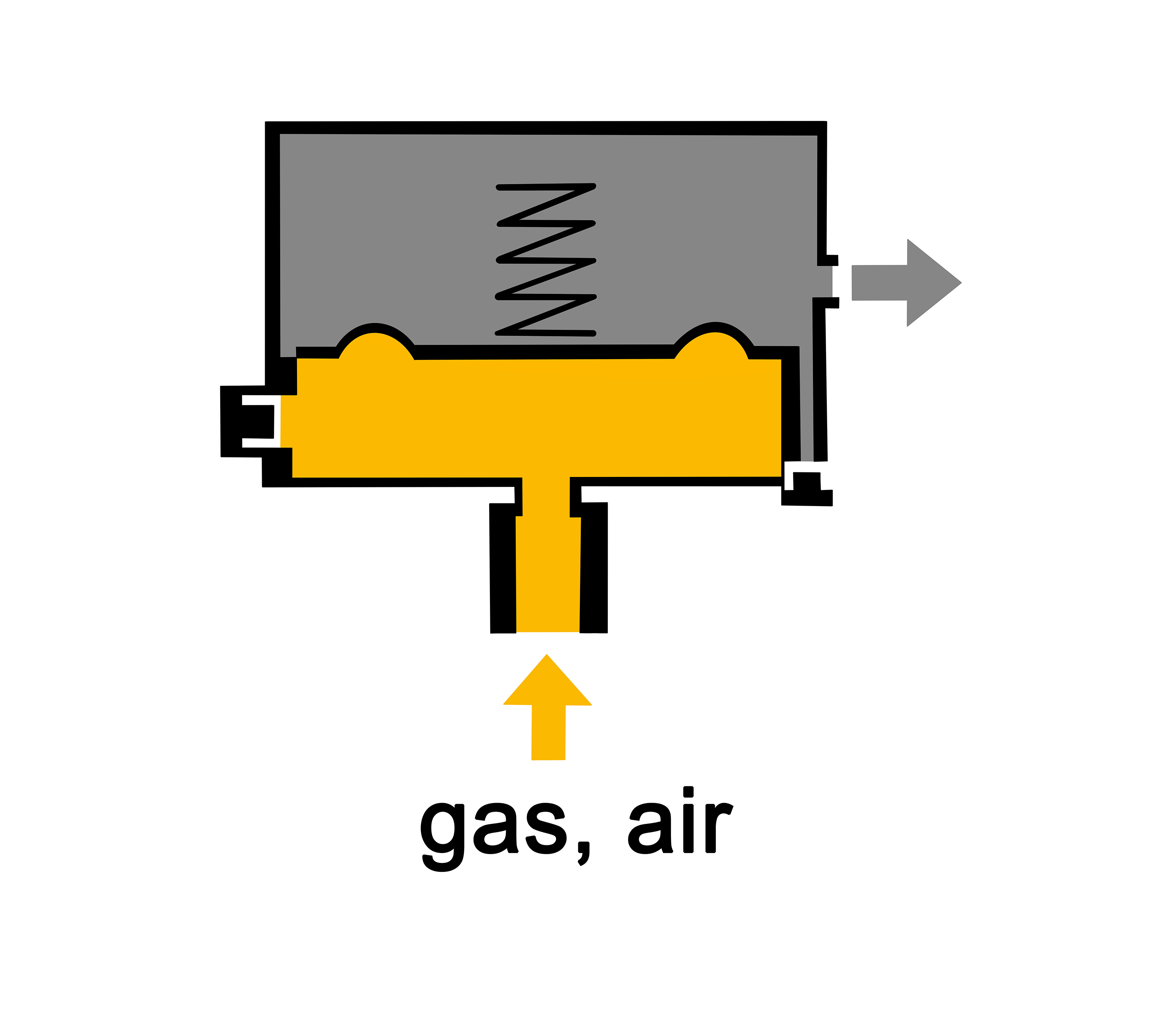

To understand better how they work, let’s take a look at a cross section.

Inside the enclosure, there is a spring and an electrical switch. The spring determines the switching pressure, which can be adjusted using a dial, or fixed with a predetermined set point at the manufacturer’s facility.

The spring tension pushes against one side of a rubber diaphragm. Gas or air is piped into a chamber on the other side of the diaphragm and activates the switch if the pressure reaches the set point.

Is installation orientation important?

Yes, often installation orientation can be important for performance, as the pressure switch internals are affected by gravity. Consult the manufacturer’s installation guidelines for instructions regarding orientation. Installing a device contrary to the manufacturer’s guidance could result in less precision in the switching point, or a total loss of function.

How do I know the pressure switch is operating properly?

Let’s take an example of detecting rising pressure. This scenario is usually referred to as the “high gas pressure switch.” The goal is for the pressure switch to cause a system shutdown if the pressure rises above 2”WC. We wire the pressure switch according to the manufacturer’s schematic for sensing rising pressure; in this case, to the Common and Normally Closed contacts.

Set the dial to 2”WC.

During operation, if the gas pressure exceeds 2”WC, the pressure overcomes the spring tension and pushes the diaphragm against the switch, breaking the electrical connection. The resulting loss of signal to the burner control causes the system to shut down.

Falling pressure is monitored in the same way. This scenario is usually referred to as the “low gas pressure switch.” The switch is wired to the Common and Normally Open contacts, and the dial is set to the lowest permissible pressure for the system. If the pressure drops below the set point, the diaphragm lowers, activating the switch.

Using our 2”WC set point, while the gas pressure remains over 2”WC, overcoming the spring tension, the diaphragm is pressed against the switch and the circuit is complete. If the pressure drops below 2”WC, spring tension overcomes the gas pressure and the diaphragm drops, breaking the circuit. The loss of signal to the burner control causes the system to shut down.

Once a pressure switch is tripped, it needs to reset before the system can return to normal operation. Some models will automatically reset when the pressure returns to an acceptable value. Other models require a manual reset; someone must physically push a button on the switch to reset it.

What are the common uses of pressure switches in combustion systems?

The scenarios mentioned above, for high gas and low gas pressure monitoring, are not only common, but required according to NFPA86. You may also see a valve proving (aka tightness check) pressure switch to test for leaks in the gas safety shut-off valves.

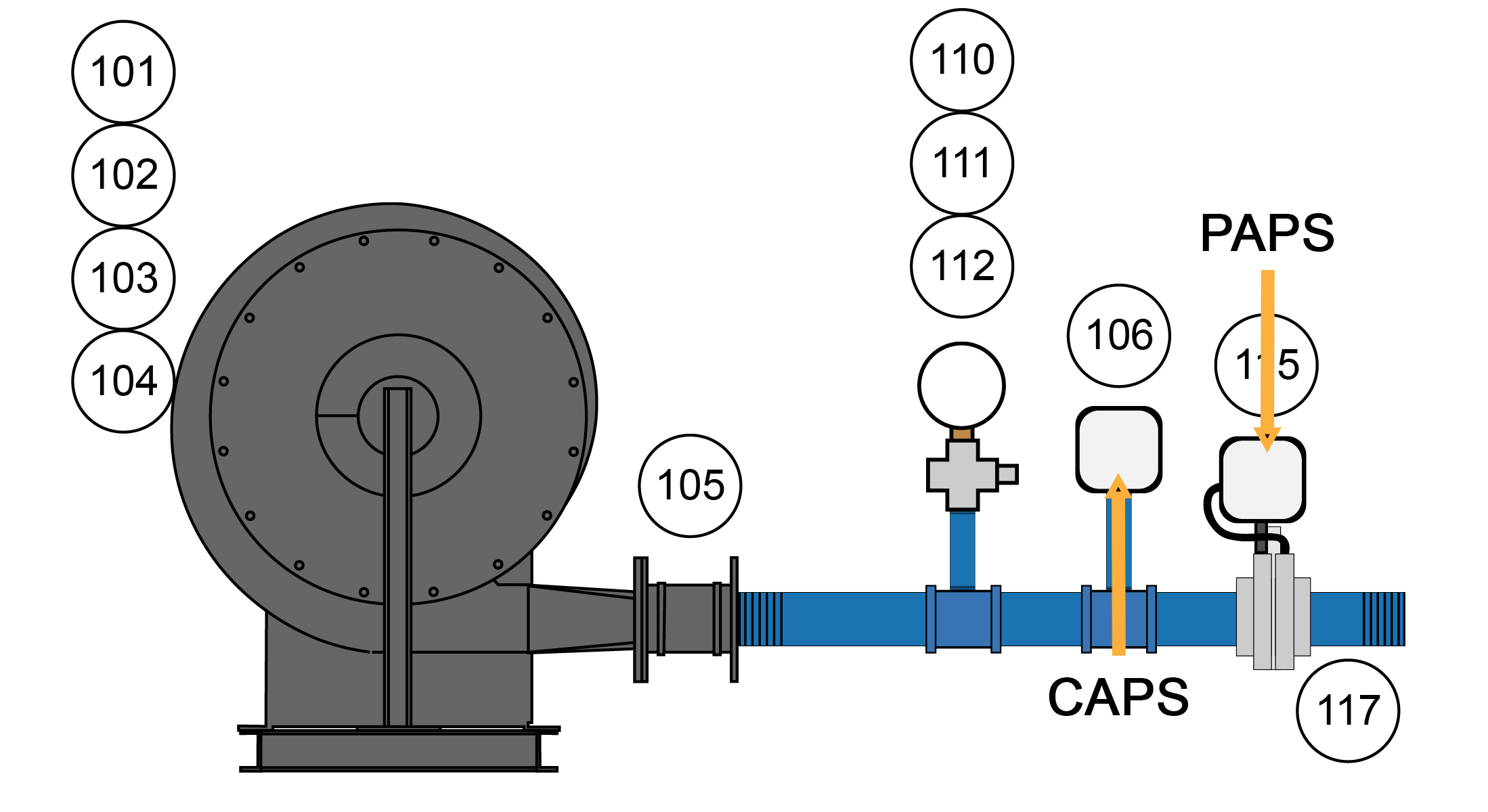

On the air side of the system, the combustion air pressure switch (CAPS), which monitors the minimum air pressure in the system, is required according to NFPA86. You may also see a pressure switch for proving purge air flow (PAPS), and another for proving exhaust blower flow.

Does it matter where I locate the pressure switches on the piping?

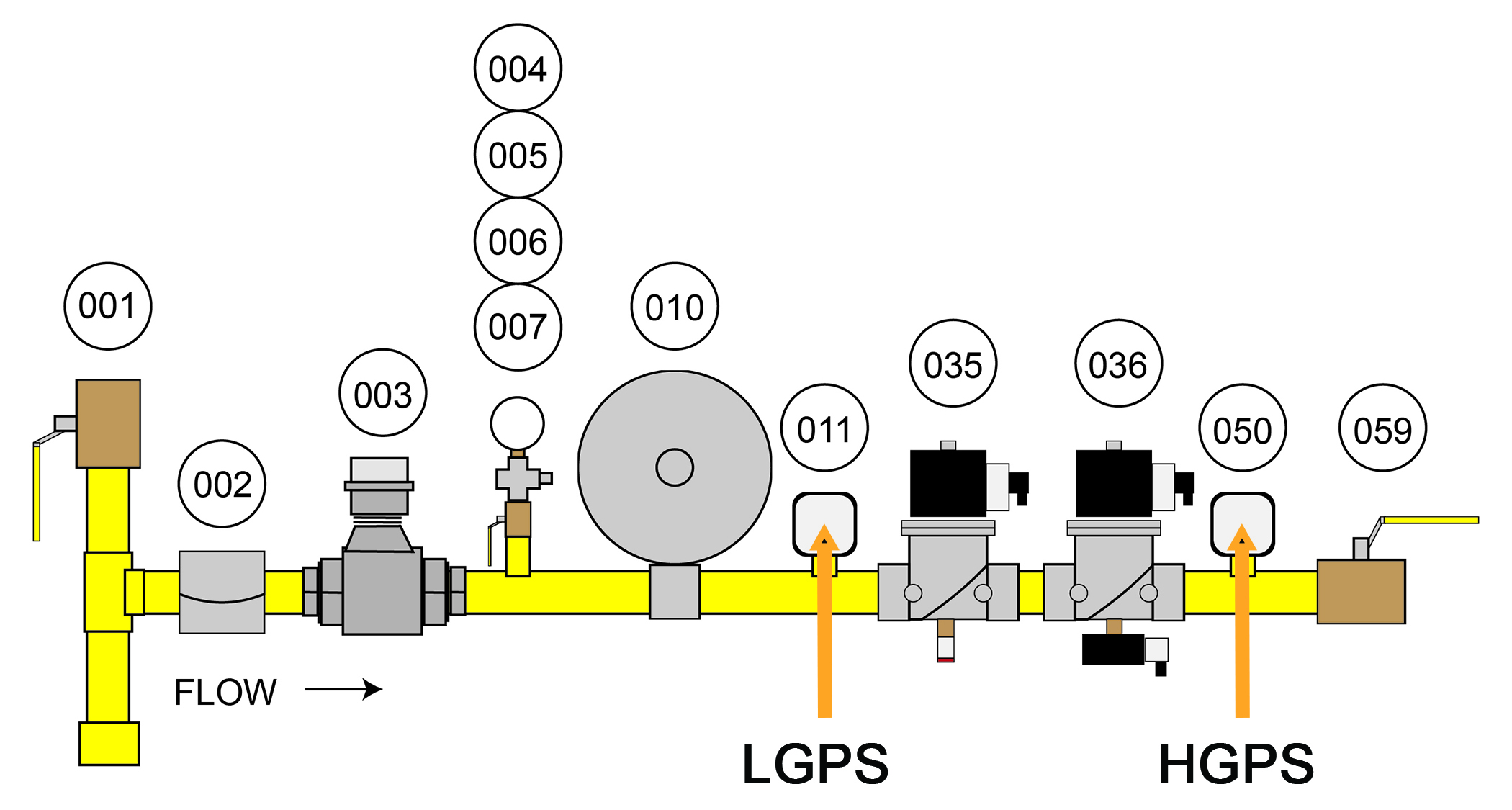

Yes, you will usually find the low gas pressure switch (sometimes abbreviated LGPS) upstream of the safety shut-off valves but downstream of the pressure reducing regulator on the main gas train. Because the LGPS monitors the minimum allowable system pressure, installing it upstream of the safety shut-off valves means you aren’t factoring in the pressure drop across those valves in the pressure seen by the LGPS.

The high gas pressure switch (HGPS) is usually found downstream of the safety shut-off valves. This switch monitors the maximum allowable system pressure. It’s not unusual to see intermittent spikes in the system inlet pressure, and the pressure reducing regulator needs a little time to normalize. By locating the HGPS downstream of the safety shut-off valves, and so with the benefit of the drop in pressure seen across those valves, you can help mitigate nuisance shut-downs which may be caused by pressure spikes.

Can I use the C911-P pressure switch for differential gas pressure?

No, our C911-P pressure switch can be used for low and high gas pressure monitoring and in valve proving systems, but it cannot be used for differential gas pressure monitoring since the “low” or “negative” side of the pressure switch is in the same chamber as the switching contacts of the switch — which arc!

However, C911-P pressure switches are suitable for differential measurement of inert gases, such as air.

My high gas pressure switch keeps tripping when I turn on the SSOVs. What’s going on?

There are a few things to check in this scenario. First, is the pressure switch setting correct? Second, are there leaks in the system that cause the pressure reducing regulator to bounce (fluctuate high) as it tries to adjust the gas pressure on startup? Third, does a sudden shutdown of the system while at high flow cause the velocity pressure of the gas flow to be converted to a high static gas pressure?

If you’re experiencing this issue, give us a call — we can help!

How do I know if my pressure switch is broken?

If your pressure switch seems to be faulty, there are a couple of things to check before replacing it. If your switch has an adjustable set point, start by checking the set point is correct (the correct system settings should be found on your combustion schematic).

If the set point is correct, the next step is to check the system pressure. Use a manometer to read the pressure in the line, the same pressure seen by your pressure switch. It’s possible the pressure switch is operating correctly, and there’s an issue elsewhere, resulting in line pressure that is either too low or too high for safe system operation.

There may be a mesh screen or filter media on the inlet port of the pressure switch. Turn off the gas flow and remove the switch to examine this. If the port is clogged, clear it and then test the switch again.

If the line pressure is as expected and there’s no obstruction to the pressure switch inlet, examine your wiring. Consult the manufacturer’s wiring diagram, and keep an eye out for damaged wires, especially if the system has been in service for some years.

At the end of these checks, if the pressure switch still isn’t working, it’s time to replace it.

Pressure switches are consumable spare parts and should be expected to fail over time. It’s a good idea to have spares on hand so you can quickly get back up and running in the event of a failure.

There aren’t many spare parts available for pressure switches, though you can usually buy replacement covers (clear covers let you see the set point). Lights* are often available as spares too, though they may also be offered as an accessory, along with mounting hardware and electrical adapters.

*Some pressure switch models use a light to indicate the the circuit is complete.

There’s usually no point in rebuilding a pressure switch, as they’re fairly inexpensive.

Can I defeat my pressure switch to continue running while I wait for a spare?

No. Defeating any part of the safety chain is against NFPA86 code and creates an environment where personnel and property are put at serious risk. The best practice is to keep spares on hand for critical operations.

In summary

Pressure switches are small devices with big jobs. They’re integral to a safe combustion system, and often options or accessories are available to make them even more helpful to operators and maintenance staff.

C911-P (our pressure switch) is available in the shop.