A gas filter is installed upstream of all other components on an industrial combustion system. It’s a simple item with a big job.

What does a gas filter do?

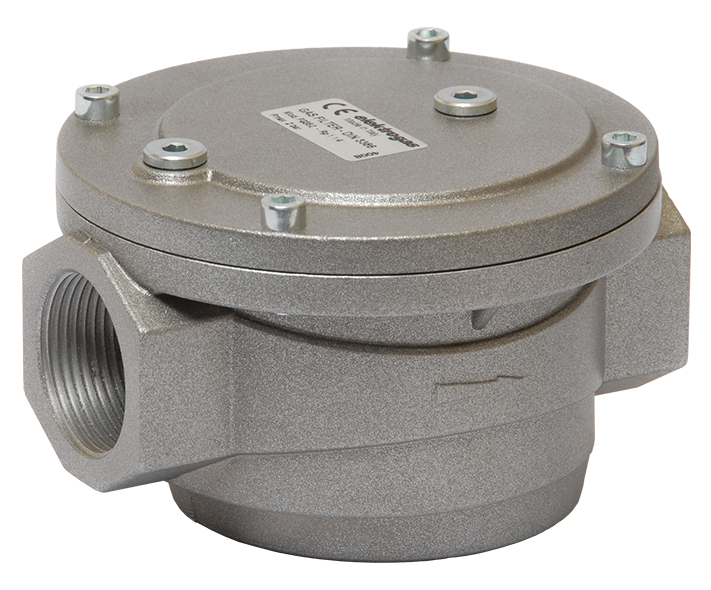

A gas filter is commonly provided with a cast aluminum housing, and the filtration is performed by the media inside. Depending on your application and the environment where your system is installed, you might need to strain out extremely fine particles. The FG from Elektrogas ships with a 30 micron filter as standard, and 5 micron media is available.

Gas filters are used to keep dirt and debris from entering the downstream components of the combustion system. Some of these components might also have strainers, or mesh screens, to guard against foreign particles. These safeguards work together to maintain the safe operation of the system.

Why do I need a gas filter?

What happens if debris is allowed to enter the downstream components? Let’s look at one example, the safety shut-off valve (SSOV). SSOVs exist to quickly cut off the flow of gas when there is a fault. If debris is allowed to enter an SSOV, it is likely to prevent proper operation, either by preventing the valve from sealing, or by causing friction that could slow the operation of the valve, or cause it to stick either open or closed.

Debris that reaches the burner could clog passages in the burner internals, reducing the flow or preventing the burner from lighting.

Why don’t I have enough gas pressure at the burner?

You should have pressure test ports on most of the components on your gas trains. Using your manometer, take differential readings across each component. If you start all the way upstream, at the gas filter, you’ll be able to verify the inlet gas pressure (from the utility drop), and you’ll be in the right position to check the next likely bottleneck, the gas filter itself.

We don’t expect the inlet gas pressure to change (although this happens, too). However, we do expect the gas filter to become clogged over time. It’s a good idea to keep spare filter media on hand for use during maintenance or troubleshooting.

How do I know to change the filter media?

Checking and, if necessary, cleaning the filter housing and replacing the filter media should be part of your preventative maintenance program. Most gas filters have an upstream and a downstream pressure test port, which can be used to determine whether the filter media is clogged.

We expect a small pressure drop across a clean gas filter. If you measure a high drop in pressure across the gas filter, chances are good you need to change the filter media.

How do I change the media in the gas filter?

First, ensure the system is off. Now, close the main gas valve. Remove the cover from the gas filter. There should be an o-ring seal between the cover and the housing. This should be replaced each time you open the gas filter housing, so it’s best to check the pressure drop before opening the gas filter.

Next, remove the old filter media and discard it. Clean out the inside of the housing by picking out any large debris. Now, use a dry rag to remove any smaller particles. Water and caustic cleaning agents are not recommended. The components downstream of your gas filter are often not designed to pass liquids through their internals.

Install new filter media from the manufacturer, and apply a new o-ring to seal the cover as you close it again.

It’s a good idea to check the pressure drop across the clean filter when you start back up. Once you’ve checked, record this in your preventative maintenance logs. Hopefully, this step simplifies your next maintenance check on this particular gas filter.

For Automation

We believe in automation for all! Visit olstrad.com and contact us to learn how we can help you automate!