NFPA86 requires burners being monitored by UV scanners to shut-down at least once every twenty-four hours. Why? The reason is safety. A UV sensor is a consumable part, and can fail in either a safe state (no flame present) or an unsafe state (flame present). A typical life cycle for a UV sensor is around 10,000 hours. If you can’t shut-down the burner once every twenty-four hours, you need a self-check UV scanner.

UV Scanner Operation

If a UV sensor fails during operation of the burner in a safe state, the burner faults out and the system shuts the gas valves. From a safety standpoint, this is ideal! If a UV sensor fails during operation of the burner in an unsafe state, the system thinks the burner is on, even if it’s not.

UV scanners are part of the combustion safety chain. A burner firing into a closed environment (such as a furnace or an oven) must employ some type of flame supervision. We need to know the burner is on (firing) when we think it’s on, otherwise we could be pouring combustible gases inside the furnace without knowing it.

Safety Considerations

Unused fuel gas can accumulate inside the furnace or oven, creating a hazardous condition to personnel and property.

Therefore, we need a solution that allows us to check the fitness of the UV scanner in applications where we cannot afford to turn our burners off at least once each twenty-four hours. In some cases, we can use a flame rod and avoid the UV scanner entirely. In other cases, we must use a self-check UV scanner.

Self-Check UV Scanners

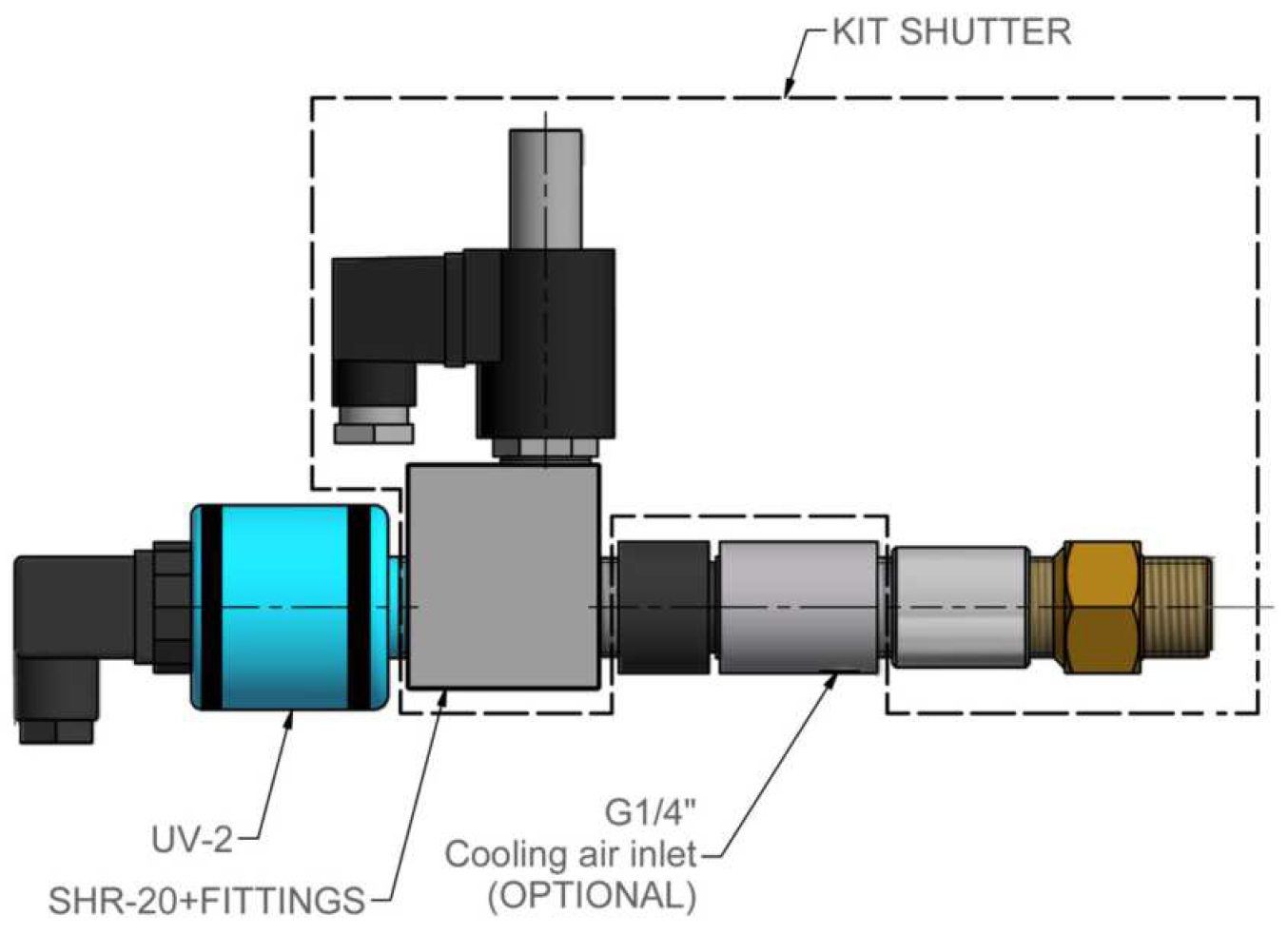

Self-check UV scanners work with the flame safety device to perform a test of the UV sensor once each twenty-four hours. A mechanism covers the UV sensor to create a known “off” condition. The UV sensor cannot “see” the flame, so it should report “no flame present.” If it reports otherwise, we know the sensor has failed in an unsafe state and we must replace it.

ESA has an innovative approach to the self-check UV scanner. Instead of a dedicated scanner for self-check, ESA offers a self-check module which is coupled to their standard UV scanner, reducing size, project cost, and waste.

UV scanners are manufacturer-specific, and must be used in conjunction with a flame safety device from the same manufacturer. ESA’s ESTRO PO (permanent operation) is CSA approved and suitable for use in applications where the burners do not cycle off, whether the flame supervision is via flame rod or self-check UV.

Contact us with questions or for more information on these fantastic products!