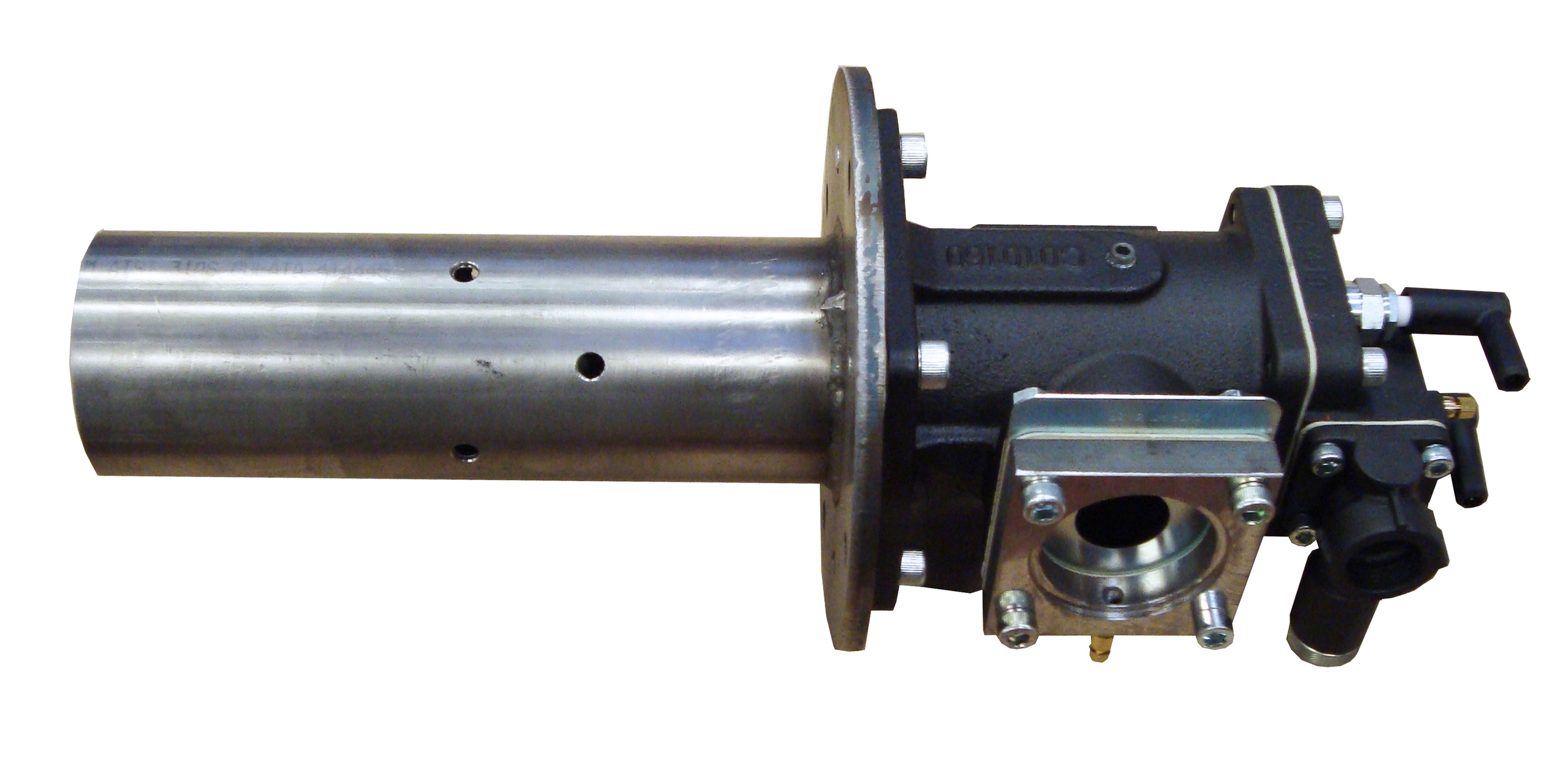

The ESA RT series are radiant tube burners for gas. RT burners are used for indirect heating; they use heat radiation to provide heat transfer inside a furnace without flame impingement. This also eliminates contamination of the workspace by products of combustion. The radiant tube connects to the burner. They come in many shapes, but typically resemble letters of the alphabet. Some of the most common examples are I, U, W, M, P, and Double P.

The RT series is not self-recuperative, but a plug-in recuperator is available. RT burners work with preheated air up to 930°F.

RT burners utilize double air mixing. This means the primary air mixes in the crossflow head, resulting in a twisting flame. The secondary air, which enters the chamber through special holes in the flame arrester pipe, completes the mixing by extending the flame itself.

Double air mixing ensures less wear on the initial part of the radiant tube, which normally sees the most stress, and allows the maximum heat exchange. The result is higher efficiency and longer life of the radiant tube.

Setup of the RT series of burners is simplified by pressure taps that allow the measurement of gas and air flow rates. The volumetric air/gas ratios normally used in radiant tubes burners are 12:1 or 13:1. The RT series can work with cold air and, using special smooth or finned exchangers, with preheated air up to 930°F, allowing energy savings of around 25-30%.

Common applications include:

-Tanks immersed at high temperatures in salt bath furnaces or in the melting of light alloys

-Quenching furnaces

-Bell or pit furnaces

-Furnaces for food processing.

For Automation

Please visit olstrad.com to learn more about our automation processes!