It’s common for an industrial plant to have openings to in the roof, especially when these plants have furnaces or ovens. A vent line allows excess combustible gases to exit to atmosphere, and a flue might allow the same for products of combustion inside the furnace chamber.

Placement of these vents and flues should be heavily monitored, because missteps can result in problems that may be difficult to diagnose.

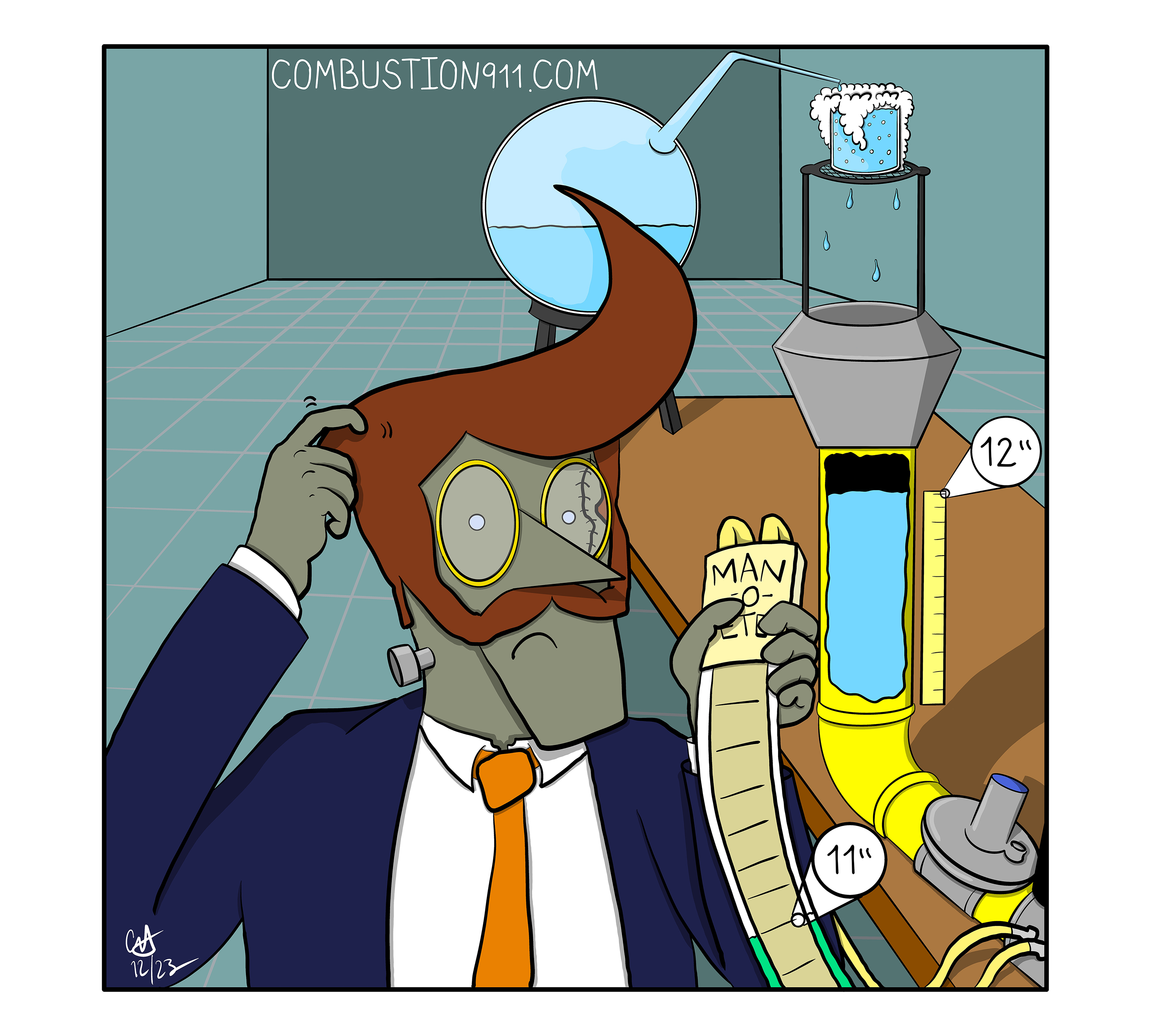

Consider a case from our troubleshooting history. Our customer called, suspecting some defect with the equipment they’d recently purchased. They verified 11 inches water column of gas pressure at the safety shut-off valves, but very little pressure at the burner. We suggested there may be a blockage in the pipe, between the regulator and the burner, with pressure exceeding 11 inches.

As it turned out, the burner was firing “up,” toward the ceiling, and a flue was there, far enough out of range so it was not in danger from the heat, but allowing rainwater to drop into the burner, which migrated to the vertical pipe between the burner and the regulator.

The result was a 12 inch “column” (the pipe) of water, and an inch more than the gas pressure could move.

Contact us with questions! We’re always happy to help.