Industrial furnaces require periodic maintenance to ensure efficiency and continued operation. Much of this maintenance can be performed by properly trained plant technicians, rather than relying on outside support.

Depending on size and design, your furnace probably has two main input lines: one for natural gas (or some other combustible gas), and one for air.

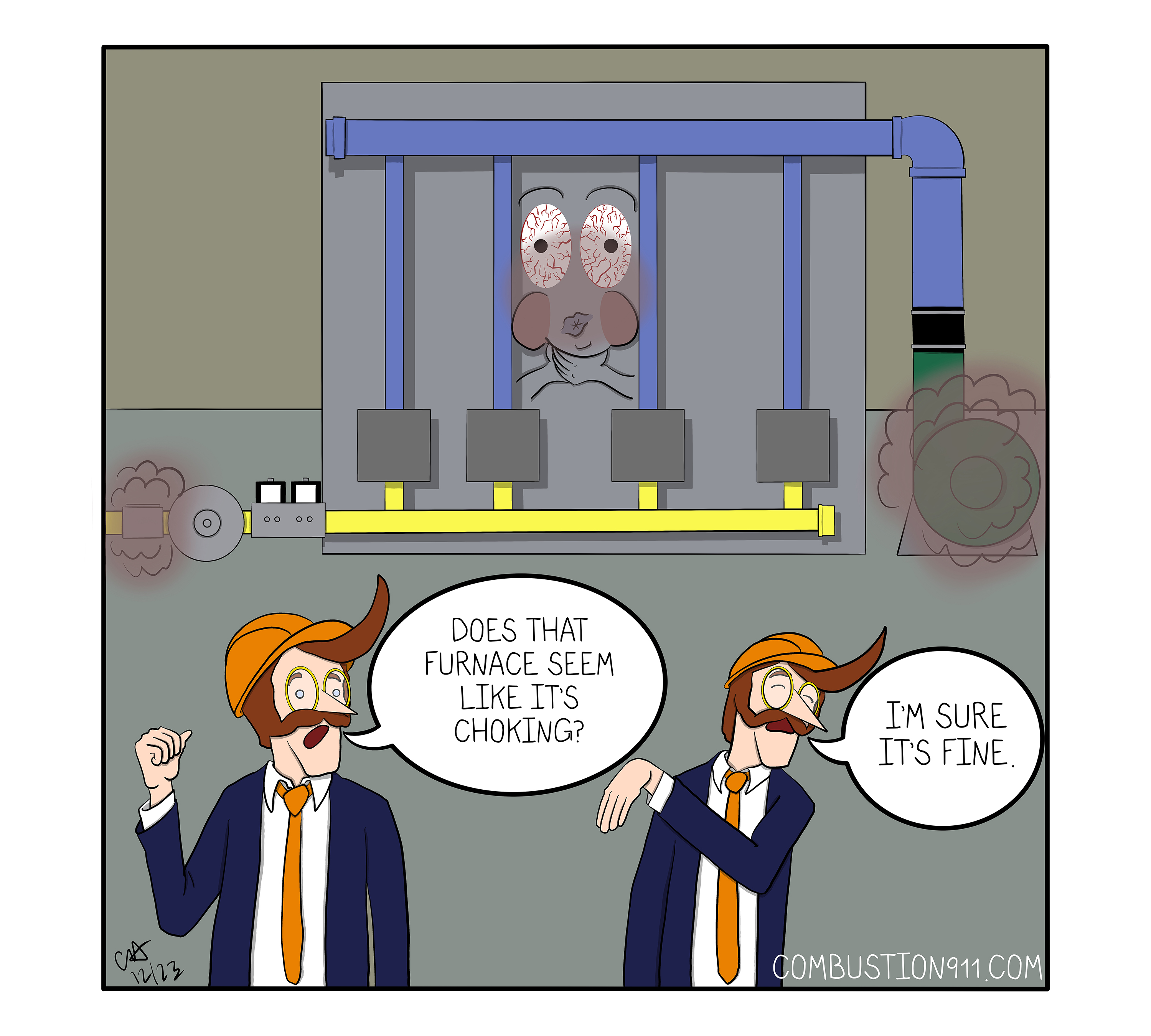

Filtration on these lines is key to the continued operation of the downstream parts, like regulators and shut-off valves. Over time, these filters may become clogged with debris. How often they need to be cleaned (or the filter media changed) depends on plant conditions and system design.

Your combustion schematic ought to show you how much pressure to expect in each line, and you can check this during operation using a manometer. If you’re not getting enough pressure at the burner(s), it’s a good chance there’s debris clogging one of these filters.

Without the required gas and air pressures, your burner(s) cannot perform at their rated capacity, and your product could suffer.

Keeping your filters clean by checking them regularly helps to ensure proper furnace operation and long component life!

Combustion 911 stocks gas filters from Elektrogas, along with spare filter media. Contact us with your gas filter needs!