Butterfly valves may be used to regulate, or control flow in combustion systems. The models found on our site allow some flow even when 100% closed. Butterfly valves can be found on both gas and air lines in combustion systems. The “butterfly” part of the name actually refers to the rotating disc connected to a rod. The disc may rotate up to 90°, from fully closed to fully open and all points in between.

The smooth shape of the butterfly disc produces low torque, and their design makes them easy to install, use, and maintain.

A butterfly valve is sized based on the flow requirements of a system. Ensuring a proper pressure drop across the butterfly valve provides a suitable control range. You may achieve this drop by using a reduced port butterfly valve in some cases. The reduced port allows you to achieve the drop of a smaller valve without complicating the piping.

Butterfly valves are also selected based on the fluid temperature. High temperature butterfly valves often have a long stem, to help remove the actuator from the worst of the heat. In extreme cases, heat shields may be employed to deflect the heat away from the actuator.

Before selecting a butterfly valve, it is important to know the fluid type (air, gas, etc.), the fluid temperature, pressure (PSI), flow, control requirements, and desired pipe connection.

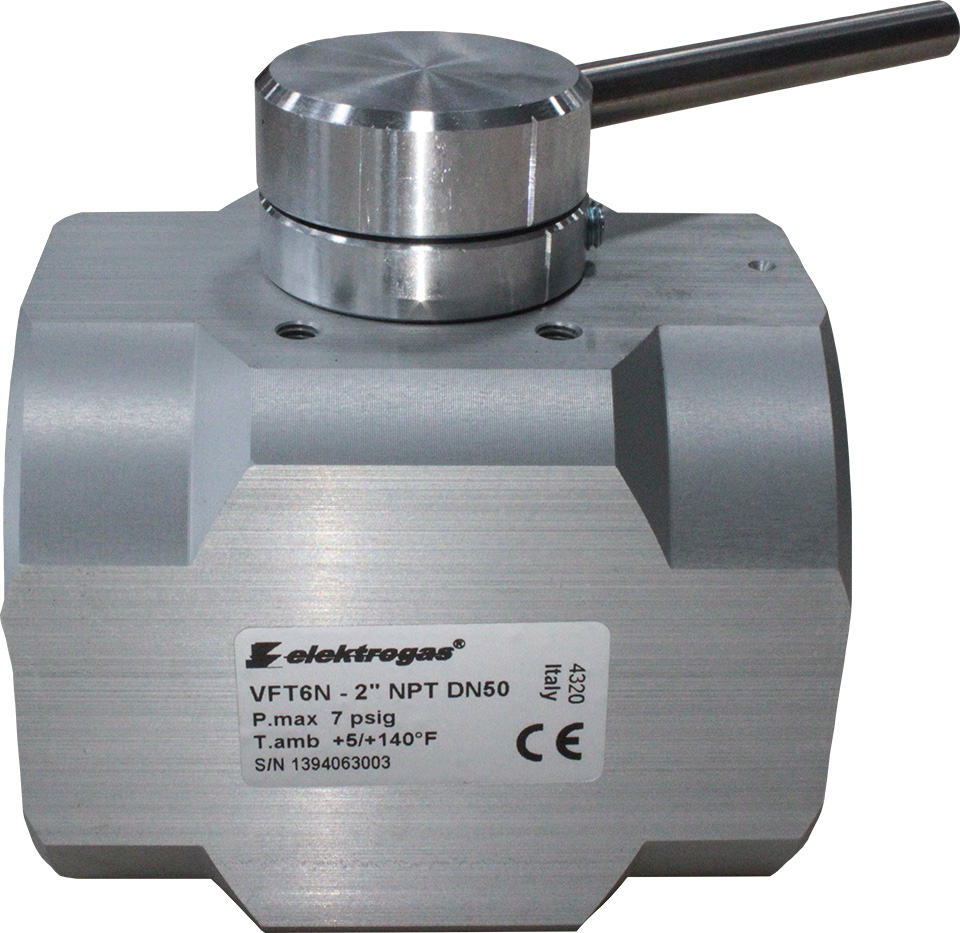

Elektrogas Valves

VF, VFT, and VFH butterfly valves from Elektrogas are made for regulation and control of both gas flow and air flow in combustion processes. These butterfly valves can be operated either manually or automatically.

Elektrogas butterfly valves are made of aluminum (VF/VFT) or cast-iron (VFH). They’re suitable for use with air and non-aggressive gases (VF/VFT), and heated air and flue gas (VFH). The VFH offers low leakage when the valve is closed, due to a disc stop.

The VFH type is provided with a double-eccentricity disc and a spring to reduce the backlash. This results in a high precision adjustment and avoids valve floating.

For Automation

Please visit olstrad.com to learn more about our automation processes!