What does an actuator do?

An actuator drives a valve, causing it to move toward the open or closed positions. Actuators are present in all automatic valves, and can take the form of a motor (servo, pneumatic, hydraulic, etc), a solenoid, or something else. With a manual valve, your hand is the actuator.

Actuators operate in a variety of ways. Actuators may be servomotor driven, with a lot of options and various degrees of control. Or they may utilize electromagnetic solenoids to open and close valves. The type of actuators used in your system are determined by your application and the system design.

When it comes to combustion systems, we commonly see actuators used to control butterfly valves, linear flow controls, and safety shut-off valves, to name a few.

What are servomotor actuators?

Servomotor driven actuators are useful for applications that require high precision control of rotary movement between 0º and 90º. The “butterfly” part of the name “butterfly valve” refers to the rotating disc connected to a rod. The actuator causes this disc to rotate up to 90°, from fully closed to fully open (and all points in between).

During set-up, you define the maximum and minimum positions for the valve, either electronically or using cams.

2-point step control servomotors use cams to set the min. and max. positions. The valve is driven to high- or low-fire when power is applied. Servomotors capable of 3-point step control also use cams, and offer a third position, which is wherever the valve happens to be when power is removed.

2- and 3-point control actuators may also incorporate a feedback potentiometer to report the position of the valve.

Continuous control servomotors are different. This type of actuator may offer electronic setting of the min. and max. positions, and allows for constant control of the valve via an analog or digital signal (depending on the model).

What is continuous control?

Continuous control means the actuator is commanded using an analog (0-20mA, 4-20mA, 0-10V) or a digital signal. The actuator may receive this signal from the PLC, or loop controller, or another device with the relevant output. This allows for automatic reactivity of the system in response to some demand (for example, heat).

There should also be a feedback signal for the system, so you always know the valve’s position.

Modulating systems might use continuous control actuators to constantly regulate flow in response to the demands of the application. Pulse-fire systems may use a 2- or 3-point step actuator instead, having only two or three points in their firing scheme. Then again, a servomotor may not be suitable for pulse-fire systems with high cycle demands. That’s where solenoid actuators come in.

What are solenoid actuators?

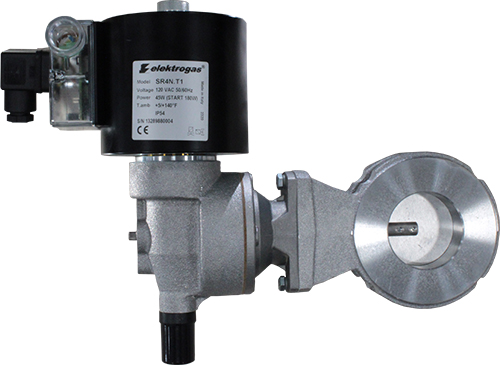

Solenoid actuators are perfect for applications that require butterfly valves to open and close, without the need for intermediate positions. Known for having a high number of operating cycles, solenoid actuators are a favorite of pulse-fire systems.

Options are usually available for selecting the rate of opening and closing (fast open/fast close; slow open/fast close; slow open/slow close). High- and low-fire positions are set mechanically, using set screws to arrest the actuator’s movement.

It is possible for some models to provide a feedback signal using a limit switch, but beware! The introduction of a limit switch might negate the ability to adjust the either the min. or max. position.

Where can I buy actuators?

Right here! We offer servomotors and solenoid actuators from Elektrogas.

Models MZ2 and MZ3 are 2- and 3-point control servomotor actuators; MZ5 is for continuous control via analog signal. All three are available in a high-torque version.

Solenoid actuator S is also available right here on Combustion 911. Please contact us with any questions regarding these products.

For Automation

We believe in automation for all! Visit olstrad.com and contact us to learn how we can help you automate