Elektrogas VRA, VLA, and VTA are a series of solenoid actuated valves used to control cold combustion air. Thanks to their expert design, they’re capable of continuous service, and are ideal for on/off or high/low control of combustion air in industrial gas burners.

Function

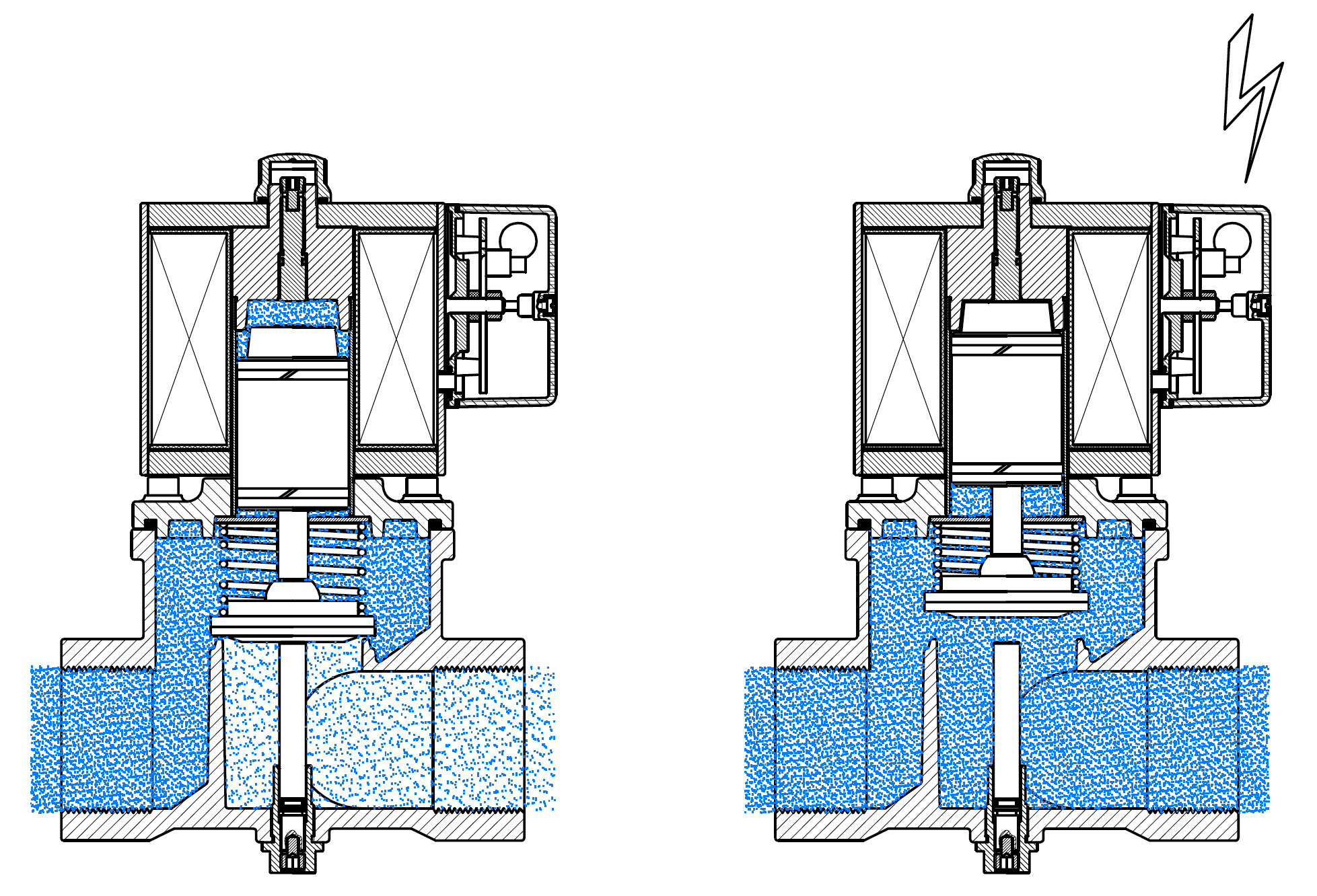

Elektrogas air valves are normally closed. When powered, the valve opens against the strength of the air flow. When de-energized, the valve closes. These valves are capable of providing a hard shut-off of air flow.

This makes VRA, VLA, and VTA ideal for on/off control, or applications that require zero air flow at certain stages of the process.

The min. and max. flow rates are adjustable. The high-fire adjustment is located at the top of the valve, above the coil, and allows you to limit high-fire air flow when 100% is not necessary. The low-fire adjustment is found underneath the valve (visible in the below diagram). Low-fire flow can therefore be increased from zero to the desired flow rate.

VRAs are fast open/closing valves (~1 second). VLAs are slow opening (~4 seconds)/fast closing, and VTAs are slow opening/closing (~4 seconds). VLA and VTA use a dampener (also called an oil brake) to slow the opening and/or closing speed of the valve.

Features

Aluminum alloy die-cast valve bodies, with a wide range of inlet/outlet connections available.

Easily adjustable high/low fire settings.

Options

Solenoid valves are ideal for the demands of a pulse-fire system, and we have a variety of spare parts available including circuit boards, DIN plugs, and dampeners (for slow opening and/or closing valves).

IP54 enclosure rating is standard, and IP65 enclosure rating is available as an option.

We stock the T1 model as standard, which includes electrical connection via DIN plug and socket, a clear electrical enclosure cover, and an LED to indicate when power is applied. Other options are available, so please ask us if our standard doesn’t meet your need.

For Automation

Please visit olstrad.com to learn more about our automation capabilities!