We often get questions about needle valves. So, we’ve put together this handy FAQ to help answer your questions!

Needle valves, also called adjusting valves, or fine-adjusting valves, are usually found downstream of the safety shut-off valves (SSOVs) on the burner gas train, though they can also be found on the burner air train. This type of valve is used to dial-in the flow of gas or air and is installed near the burner. We do not recommend using a needle valve to manually shut-off the flow of gas; a ball valve should be used for this purpose. Check the manufacturer’s literature for the specifications of the needle valve you’re using.

Function

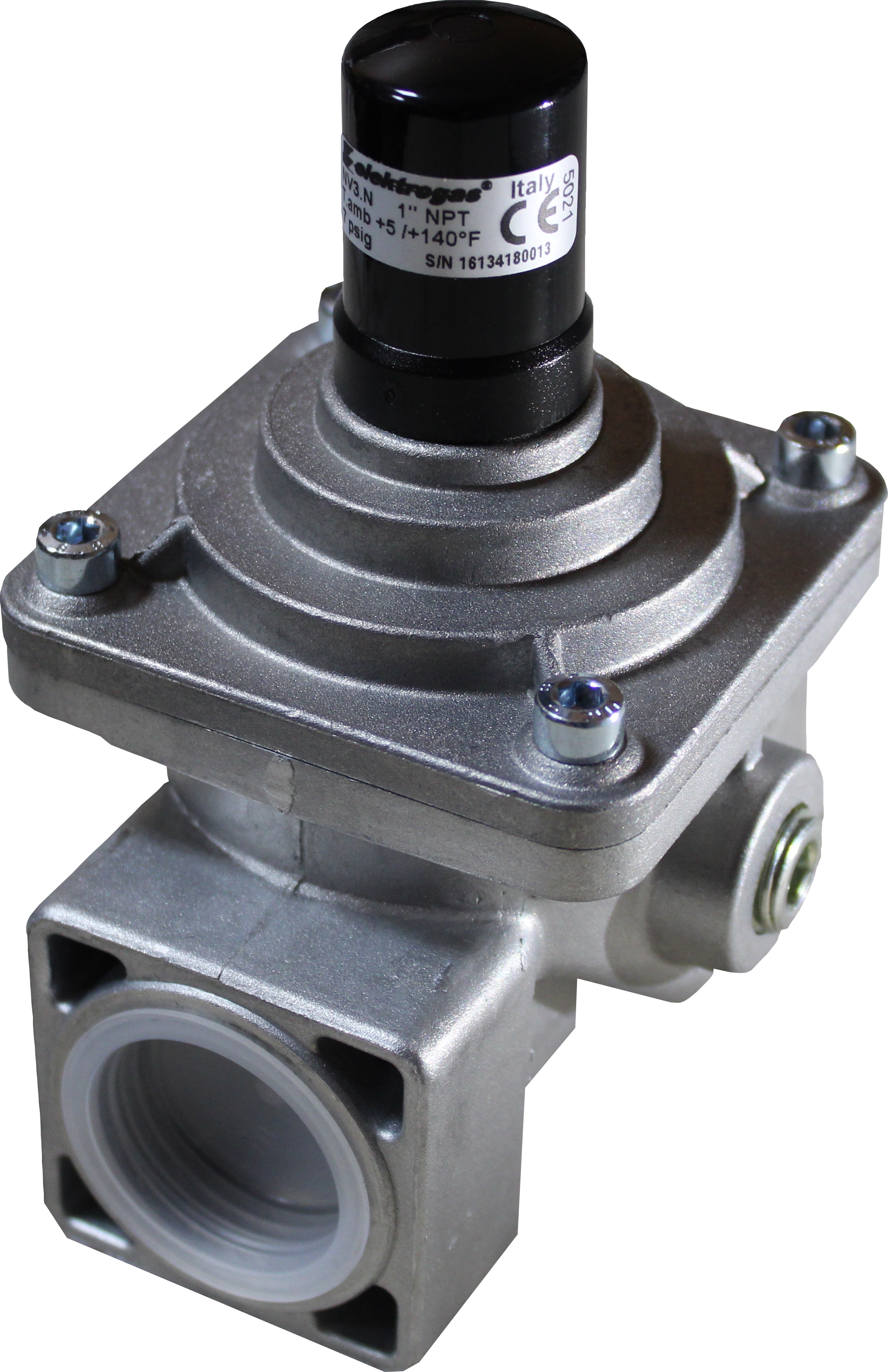

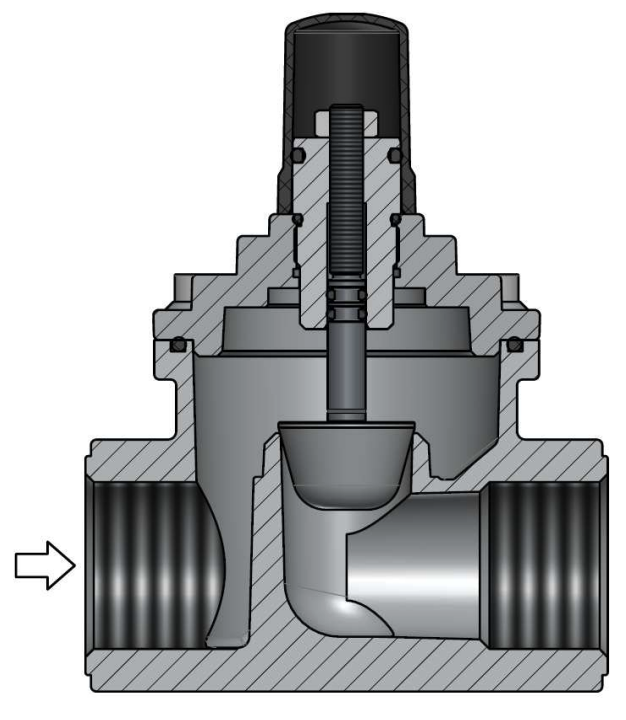

Needle valves typically have an adjustable taper plunger which is adjustable using an Allen wrench. Turning the screw increases or decreases the flow rate. When using the Elektrogas NV, turning the screw counterclockwise increases the flow. A locking nut holds the set position, and a plastic cap hides the adjustment screw to discourage tampering with the setting.

Application

The NV is suitable for natural gas, propane gas, and air, at temperatures up to 140°F, and is available in sizes 3/8″ through 2″ NPT. A special version is available for biogas or high temperature air (up to 390°F — air only!).

For Automation

Please visit olstrad.com to learn more about our automation processes!