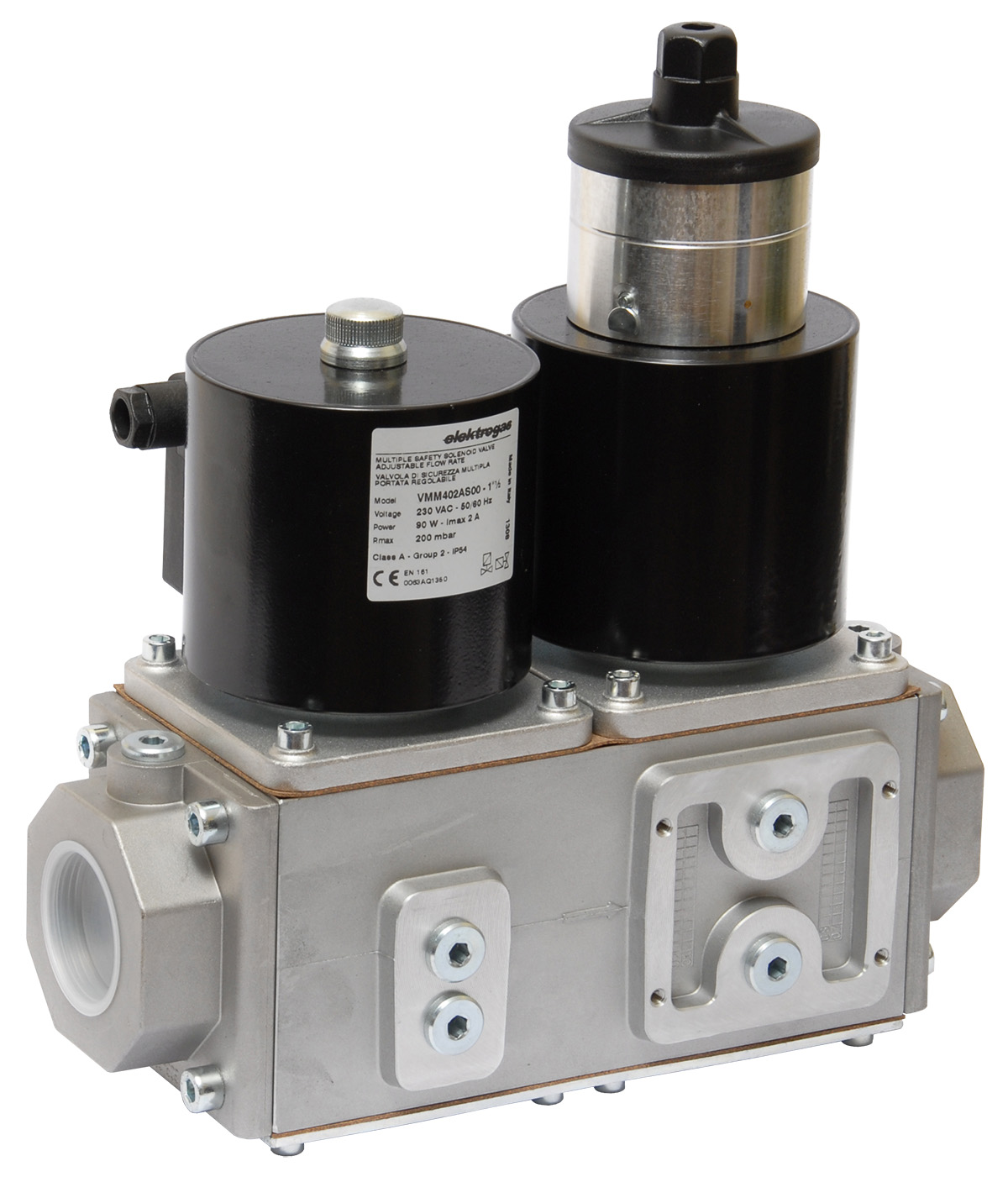

Elektrogas VMM solenoid valves are safety devices used to stop the flow of gas in a combustion system. The VMM features two separate solenoid valves in one unit. The first valve is fast opening; when powered, the valve rapidly opens against the strength of the gas flow. When de-energized, the valve closes, pushing on a seal disc which keeps the passage closed from gas. The second valve may be fast opening or slow opening. Both valves have flow adjustment. (An optional third valve may be used as a pilot).

These devices are typically installed as a safety and regulating device on gas trains, for industrial applications, and in gas-firing systems. VMMs feature inlet and outlet ports for pressure tests, even on 3/4″ and 1″ models. VMMs meet NFPA86 requirements and have versions with POC on one valve (V2) and VI on V1. Elektrogas VMM also carry FM approval.

The maximum pressure for VMMs is 7 PSI, all the way down to 2½” and 3″ sizes. Compare that with VMR and VML models which both have a max. 5 PSI for the same size. VMMs are suitable for high duty cycling.

For Automation

Please visit olstrad.com to learn more about our automation processes!