Conduit

For many years, the use of rigid or liquid-tight conduit was the standard for running wires to field devices, such as safety shut-off valves, pressure switches, and flame safety devices. Rigid conduit is thin walled metal tubing that helps to protect wires from mechanical damage and some environmental factors. Liquid-tight conduit is flexible and has a rubberized jacket, providing much of the same mechanical protection with extra environmental benefits, as it should keep moisture out with proper installation.

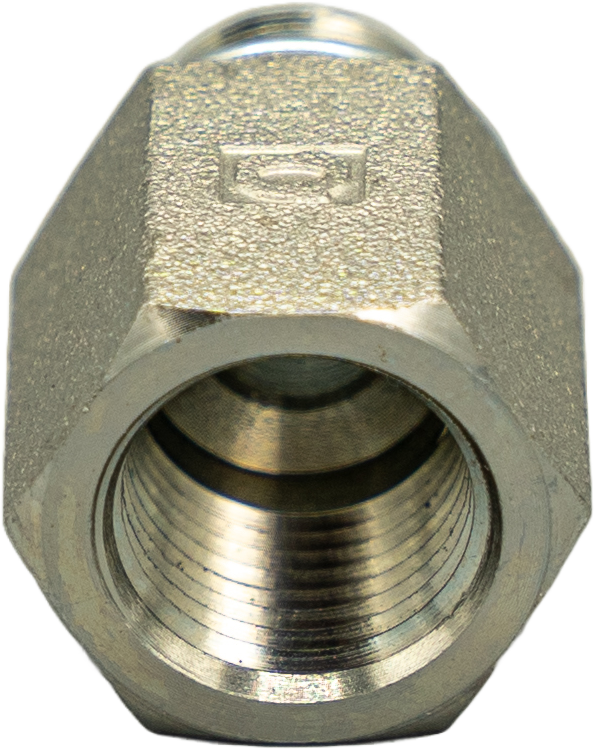

Each have their advantages, but running conduit is expensive. Aside from material costs, it takes time and planning to install conduit, and that’s before you ever pull a wire. Traditionally, conduit terminates in a threaded connection. When terminating to a pressure switch or valve, that connection is typically 1/2″ NPT in the USA.

SO Cord

SO cord is a jacketed cable containing some number of conductors. The jacket provides environmental protection and in many installations is suitable on its own, or it may be run inside conduit.

Options allow you to dictate the number of conductors, the wire gauge, and the jacket rating.

SO cord is the more economical option when compared to conduit and has been widely used for many years. A cord grip (sometimes called a cable gland) is used to cinch the cord with a thick rubber gasket, which should keep dust and moisture out of the electrical enclosure, where the SO cord terminates.

Conduit or SO cord?

The plant environment and requirements, along with local codes and standards, may dictate whether conduit must be used, either in conjunction with or instead of SO cord.

Metric Termination

You’re likely to encounter equipment in the field with a thread at the electrical connection that won’t interface easily with standard NPT electrical fittings. In cases like these, you have two options. Either use a thread adapter, or use a cord grip, manufactured for the thread type on the equipment.

Example #1: Elektrogas equipment with plug-and-socket connection

Elektrogas SSOVs, solenoid actuators, solenoid valves for air, and normally open vent valves are all available with a plug-and-socket connection, and that’s how we stock them. The socket has a built-in cord grip, but if you need to terminate to the socket with a threaded connection, you’ll need something that mates to PG9 type thread. We offer a PG9-1/2NPT adapter for this situation. These can be found in the accessories section of the relevant product pages.

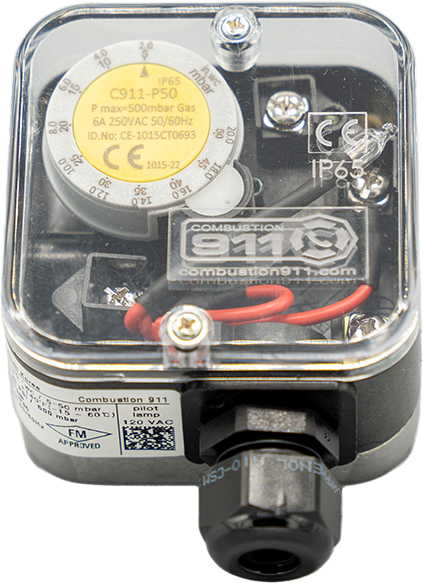

Example #2: C911-P pressure switches

Our pressure switches have an M18x1.5 threaded connection at the electrical housing. We have two accessories available (C911-PCG and C911-PADP), so whether you prefer a cord grip or a threaded adapter, we’ve got you covered.

Are there any reasons you might want to use one instead of the other?

Is there a best/recommended option?

Cord grips and thread adapters are both viable options, though we prefer cord grips. The number one reason is strain relief.

Using SO cord with a cord grip allows you to reduce the strain on the equipment. By providing enough cord length (slack), you can mitigate the danger of mechanical damage due to stress. Running conduit directly to the device can add stress to the enclosure, sometimes dramatically. Without sufficient slack, SO cord installations can have the same problem.

What are some impacts to strain? Insecure wire connections, mechanical damage to the equipment, and strange valve or proof of closure behavior are a few of the most common.

If conduit is required, consider running SO cord inside, and then using cord grips to terminate, as shown in the photos below.

Whichever you need or prefer, we’ve got you covered. Please contact us with any questions.

For Automation

We believe in automation for all! Visit olstrad.com and contact us to learn how we can help you automate!